Carbowind Products Manufacturer

CarboWind, a dedicated brand for wind energy aftermarket, helps enhance the operational efficiency and reliability of your energy plant. Being founded for the wind energy sector, various products like wind turbine brushes, power brush holders, slipring units, etc., offer improved functionality and reduced downtime. Hatim Carbon ensures that CarboWind’s range of products helps make wind power more efficient and brings more advancement in the field of wind energy.

Connect With Us

Need more help?

+91 33 4044 5152

Our Product Portfolio

Specially treated copper and silver graphite components.

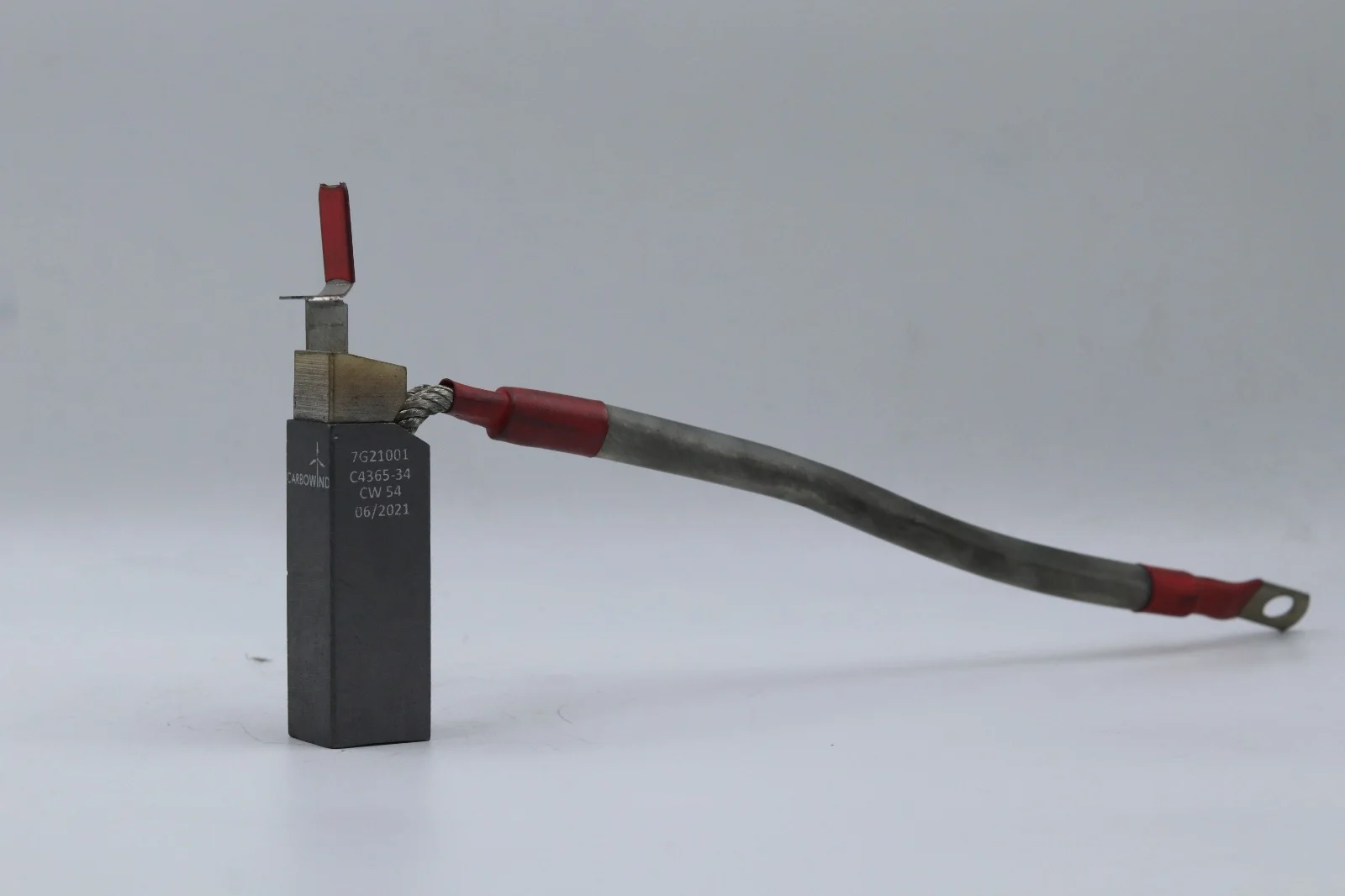

Our phase carbon brushes are specifically designed to display low wear even with the harshest of environments and highest of speeds.

Reliable copper and silver graphite brushes.

Elevate safety and performance with our superior earthing carbon brushes – a reliable choice for optimal grounding.

Includes carbon brushes, holders and spring systems.

This high-metal component redirects lightning current to protect the shaft, gearbox and bearings from an electrical surge. Our protection systems have saved companies millions in maintenance costs.

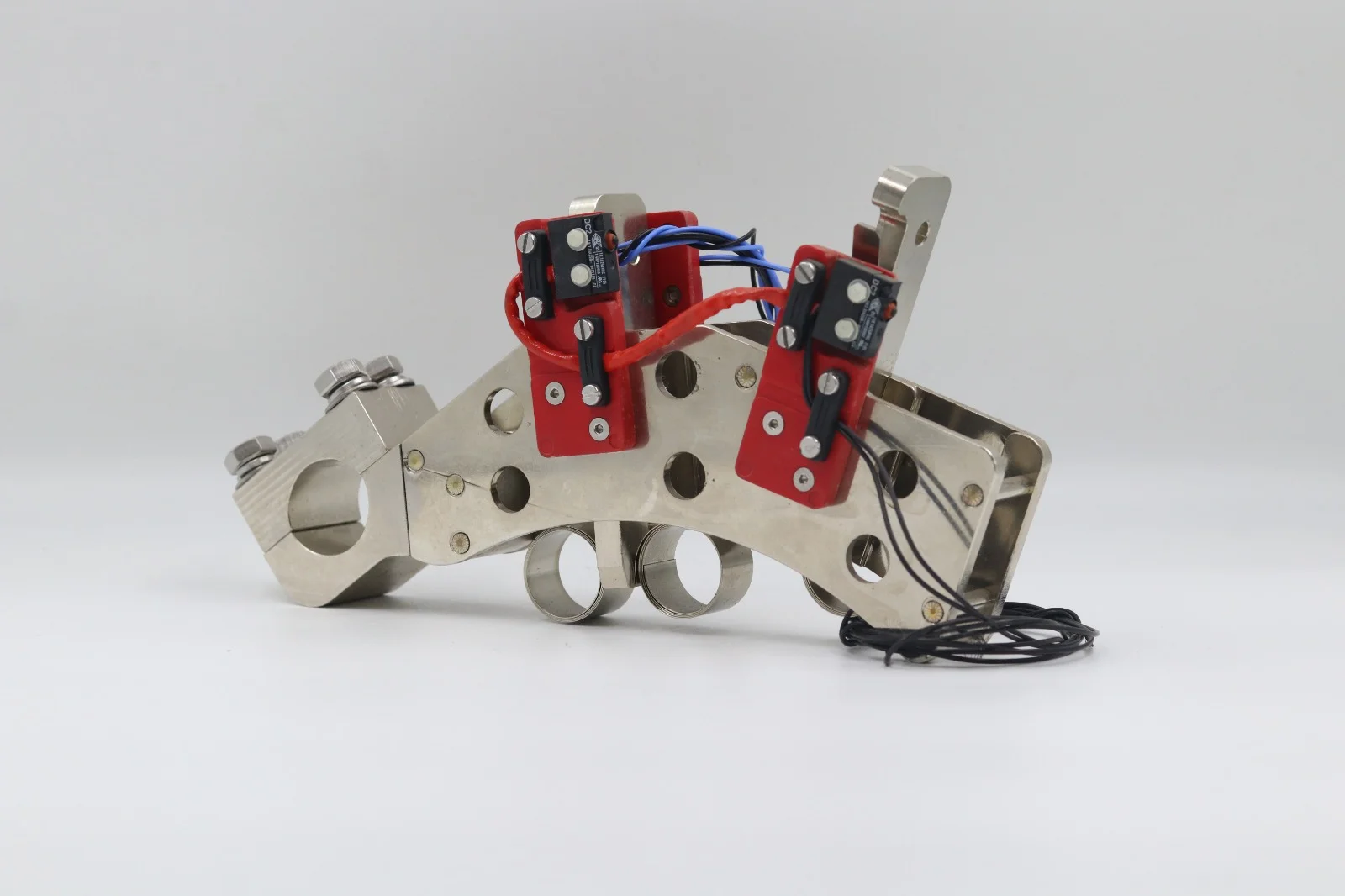

Includes brush holders, rocker assemblies, springs and limit switches.

Supporting the electric transfer from the graphite to the transformer, our holder assemblies not only ensure low electrical losses, but also assist in precision monitoring to reduce downtime of the turbine.

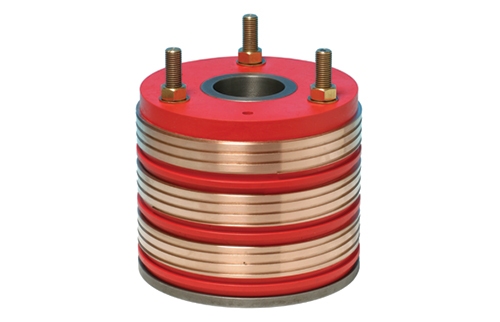

Includes phase and pitch control sliprings.

With our international associations and partners, we have access to high quality slipring units that is catered to the consumers’ application and need.

Includes heat exchangers, couplings, wind vanes and more.

Parallel to our electrical spares line, we also stock and sell mechanical turbine measuring units to ensure that real time data is accurately monitored.

Different CarboWind Products at Hatim Carbon

Carbon brushes for wind turbines: – Carbon brushes are essential components in electrical machines, including generators and motors. At CarboWind, our carbon brushes for wind turbines are made using premium-grade materials that ensure complete conductivity, low friction, and high durability. These wind turbine brushes and other carbon burses help facilitate efficient electrical contact with rotating components, ensuring smooth operation and minimal wear.

Slipring units: – Slipring units help transfer electrical power and signals between stationary and rotating parts in machinery. Hatim Carbon offers a range of high-performance slipring units under the CarboWind brand that is designed to meet demanding operating conditions. It features robust construction, advanced insulation, and precision engineering to ensure smooth power transmission and signal integrity. Whether for large-scale generators or complex machinery, slipring units deliver reliability and longevity, making them ideal for CarboWind energy plant installations.

Power brush holders: – Power brush holders are essential in securing and positioning carbon brushes within electrical machines. Hatim Carbon, the wind turbine brush manufacturer, offers power brush holders with attention to detail, employing high-quality materials and precise engineering techniques. The brush holders can be mounted easily while offering reliable contact pressure and easy maintenance.

Brush gear accessories: – Brush gear accessories complement carbon brushes and power brush holders to optimize the performance and longevity of electrical machinery. Hatim Carbon offers a unique range of brush gear accessories under CarboWind, including springs, limit switches, shunts, insulators, and terminals. These are manufactured with the same standards as our other products. The accessories ensure secure assembly, effective electrical contact, and minimal maintenance requirements. Whether for routine maintenance or system upgrades, our brush gear accessories provide reliable support for CarboWind energy plant operations.

Benefits of Using CarboWind Products

Flexibility in design

Our range of CarboWind products, like wind turbine brushes, holders, and accessories, are crafted with a complete focus on flexibility in design. Whether your plant has a small layout or is complex with a lot of configurations, the CarboWind energy efficient products can easily fit all your space requirements. The adaptability feature allows for optimal utilization of resources and boosts efficient integration with existing infrastructure. This will help enhance the overall efficiency of the energy plant.

Reduced energy losses

Similar to different industrial setups, efficiency is the basic need in energy production. CarboWind energy products by Hatim Carbon focus on minimizing plant energy losses. Using advanced engineering techniques and flexible designs, the range of carbon products helps reduce wastage and streamline the energy flow. This eventually helps in cost savings and makes every unit generated count to its full potential.

Lightweight and durable

Equipment durability is non-negotiable when setting up an energy plant. CarboWind caters to a lightweight yet durable carbon product for wind energy aftermarket. It combines advanced materials' strength with a lightweight design's practicality. This brings ease in transportation without hampering the products and makes it simple to install. It helps bring reliability and improved performance even in the harshest operating conditions.

Reduced carbon footprints

Wind power carbon brushes, turbines, and other CarboWind products help create a sustainable solution in energy plants. While going green and reducing carbon footprint is essential, choosing the right products can make a huge difference. CarboWind products are made with sustainability in mind, using eco-friendly materials and energy-efficient technologies to reduce environmental impact. It helps lower the carbon footprint and demonstrates a commitment to go green while running an energy plant.

Resistant to corrosion

Corrosion can impact the durability of the machines and directly affect the performance of your energy plant. While it will lead to costly repairs and downtime, choosing Hatim Carbon CarboWind for wind energy solutions will ensure to add corrosion-free products to your plant. This will add to uninterrupted operations and will improve the service of life of your energy plant.

Recyclable

When talking about sustainability, sticking just to energy saving is not enough. CarboWind designs are made using materials that are recyclable, making you contribute to the circular economy and minimize waste. It allows your energy plant to make environmentally friendly decisions and be responsible for maximizing resource efficiency.

Enhanced energy efficiency

Increasing energy efficiency is key to achieving peak performance in an energy plant. CarboWind uses state-of-the-art technologies and design principles to enhance energy efficiency, optimize energy conversion processes, and reduce operating costs. With CarboWind, you can achieve higher output with lower input, promoting new levels of efficiency and profitability for your energy plant.

Easy maintenance

Smooth operation depends on regular maintenance, and power brush holders, turbine brushes, etc., offer ease of maintenance. Accessible components, intuitive servicing procedures, and complete support ensure minimal downtime and maximum uptime for your energy plant.

Optimized load distribution

Efficient load distribution helps in balancing power generation and consumption in an energy plant. CarboWind energy products for aftermarket allow for optimizing load distribution, preventing overloading, and ensuring stable performance across the power system. The optimization maximizes reliability and minimizes the risk of downtime, keeping your energy plant running smoothly under all operating conditions.

Why Us ?

- 3-7 day guaranteed delivery for all brushes

- Availability of multi-brand components

- Rigorously tested parts [300 hours life-cycle tests]

- Low brush wear during high wind seasons

- High pressure die casting brush holder assemblies

- Wide product range; One Stop Shop

- Approved brush grades for all generator makes

- On-Site troubleshooting capabilities

- Design & grade suggestion capabilities for custom applications

Being in the wind power business, focusing on efficient and reliable solutions that can help yield more energy units in less wastage is crucial. It not only helps you take a cost-effective approach but also makes you invest in a sustainable solution for your power plant. CarboWind products at Hatim Carbon offer wind turbine brushes, carbon brush holders, slipring units, and many other products that contribute to smooth functioning of the wind energy plant. Hatim Carbon ensures that multi-brand components are made available to you within 3 to 7 days. All products are rigorously tested with a 300-hour life-cycle test and design suggestions for custom applications. The wide product range with on-site solutions for troubleshooting makes Hatim Carbon your one stop solution to all CarboWind products for your energy plant.

Most Popular Questions.

The replacement frequency of carbon brushes in a wind turbine depends on various factors such as operating conditions, environmental factors, and the specific type of brushes used. Regular inspections are recommended, and we can assist in determining an optimal replacement schedule based on your turbine's unique requirements. Generally, one set of carbon brushes should last around 8-10 months of regular use.

It is generally not recommended to mix carbon grades on a slipring. Using uniform carbon grades ensures consistent performance and minimizes wear. Mixing grades can lead to uneven wear and compromised electrical contact. Our experts can guide you in selecting the right carbon grades for your specific slipring application.

Excessive carbon brush wear may indicate issues with alignment, pressure, or the quality of the brushes. Our technical team can provide a comprehensive analysis of your system, identify the root cause, and recommend solutions to optimize brush performance and reduce wear on your slipring.

Yes, accessories play a crucial role in the overall performance and longevity of your wind turbine system. They include the correct brush holders, limit switches, and grounding solutions, among others. These accessories directly contribute to system reliability and can enhance the efficiency of your turbine.

We offer comprehensive assistance, including guidance on selecting the right carbon brushes, brush holders, slipring units, and accessories for your wind turbine. Our team can also provide on-site technical support, help with installation and maintenance queries, and offer custom solutions to meet your specific requirements. Contact us for any assistance you may need throughout the lifecycle of your turbine system.